High quality safety Satisfy customers

Regulating Valve Series

ZJHM

Sleeve type regulating valve

Production process control system for quality and process conditions.

This product is composed of a new pneumatic multi-spring film actuator and a low flow resistance sleeve valve. The characteristics are as follows:

1, the use of balanced spool, unbalanced force is small, allowing large pressure difference, stable operation.

2, the valve seat guide surface is large, can improve the shock caused by eddy current and impact, and reduce damage.

3, compared with the ordinary single and double seat regulating valve noise reduction of about 10dB.

4, simple structure, convenient installation and disassembly maintenance.

ZM(A/K)P-D

Pneumatic film low temperature single seat regulating valve

Pneumatic film low temperature regulating valve is a single - seat regulating valve, double - seat regulating valve deformation products. It is different from the normal temperature control valve in the use of a long neck on the valve cover, so that the packing at room temperature work. Suitable for -60 ~ -250℃ low temperature strong state medium (such as liquid oxygen, liquid nitrogen, etc.) regulation. To ensure the adjustment accuracy, must be equipped with valve positioner.

TECHNICAL STRENGTH

01

R&D design

Technology creates the brand, innovation accomplishes the dream.

Focus on creating excellence, quality is beyond doubt.

Perfect service system, professional and trustworthy.

02

Raw material testing

In order to provide high quality products

The company is equipped with advanced testing equipment and perfect testing methods.

Established a strict requirements of the quality control team.

We have realized the whole process of quality control from raw material testing to production process control, product and application

products and application of the whole process of quality control

03

Elaboration

The company has excellent production and processing manufacturing equipment.

Including machining centers, CNC lathes, CNC milling machines, CNC drilling machines,

CNC sawing machine, precision grinding machine, super-large precision vertical lathe and boring machine,

Plasma spray welding equipment, automatic digital submerged arc welding machine,

automated spraying assembly line, heat treatment furnace and other vehicles,

Milling, boring, drilling, welding, grinding, heat treatment and other machining and special equipment more than 200 sets / sets, the annual production capacity of more than 20,000 tons.

The annual production capacity is more than 20,000 tons.

04

Process testing

Modern testing equipment and professional testing team

Realize the perfect presentation of the electric construction valve

High-quality products developed by independent technology

Fully reflects the unremitting pursuit of the brand internationalization strategy of DECC.

05

Delivery site

Precise control of product performance always allows for safe and worry-free operation.

This is our commitment to our customers

06

Testing

Simulation test for severe working conditions

-196°C low temperature test

High temperature fire test

Ensure high precision, stability and excellent quality.

Provide professional and efficient fluid control solutions

PRODUCTS & TECHNOLOGY

Strong technology, perfect craftsmanship, excellent equipment, and comprehensive and fast after-sales service have won the trust and praise of a large number of users.

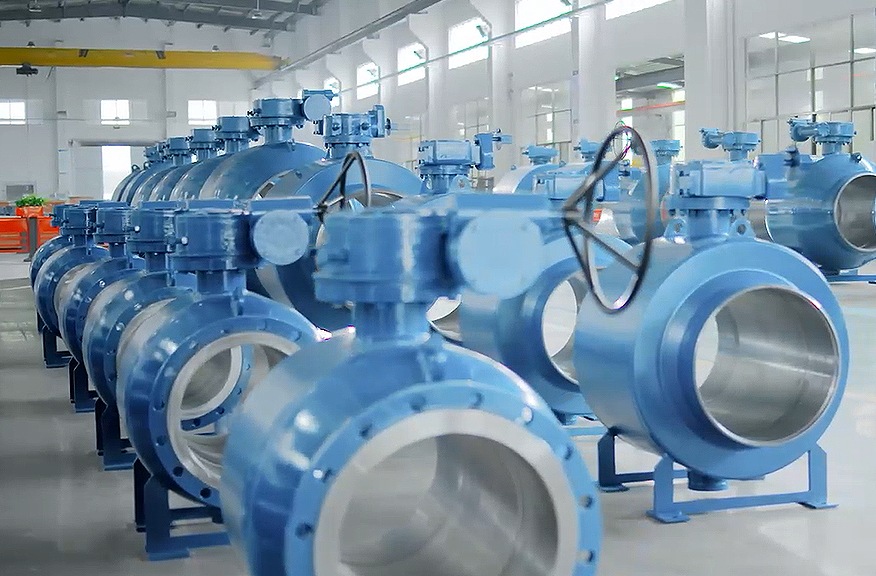

Fully Welded Ball Valves

Three eccentric full metal hard seal butterfly valve

The ball valve adopts double piston sealing structure, providing three layers of sealing.

The patented technology of automatic compensation sealing achieves long life, clears impurities and never jams the ball.

Three eccentric all-metal hard seal butterfly valve, with wear-resistant, two-way sealing performance, the

The technology of movable valve seat is suitable for high temperature, ultra-low temperature, and the harsh working conditions of many impurities.

3D PRODUCTS VIDEO